The rotary shaft oil seal is an indispensable component in any lubricated rotating equipment.

The •FP• oil seals provide the right solution to every sealing problem.

•FP• rotary shaft oil seals are produced according to modern engineering techniques with high-performing materials, as requested by industry specifications.

Download:

G

Technical features

Materials

Rubber End Covers are designed for static applications, and to act as a plug or barrier. They are used in common applications, and specially for sealing in the gearbox as an end cap. The temperature and the pressure ranges are depending on the material.

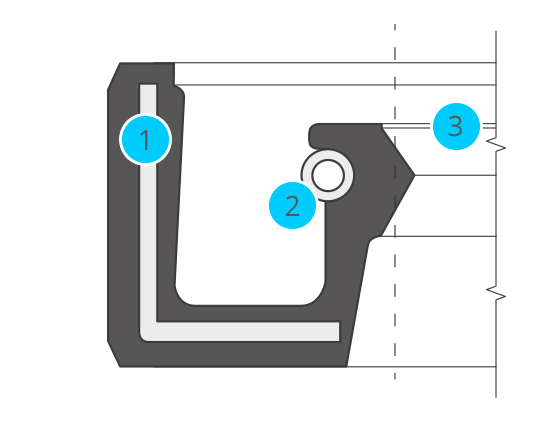

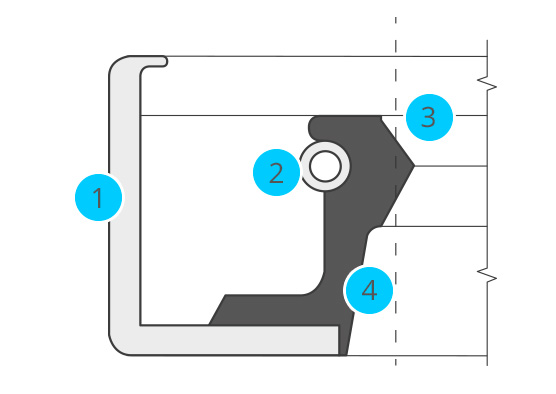

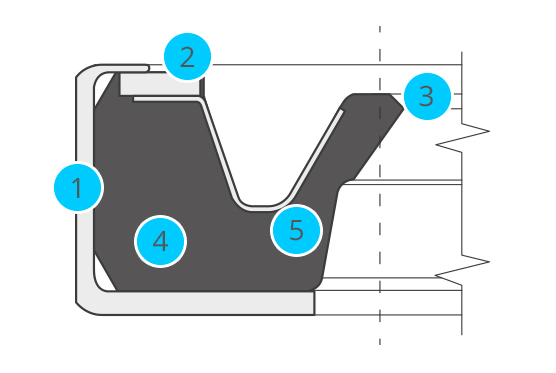

Oil seal with flexible reinforced textile-rubber back and rubber sealing lip with garter spring.

A clamping plate is required.

The seat of the garter spring (stainless steel) is designed to prevent its accidental loss during assembly. Particularly useful for “blind” installations on site.

Garter spring also available encapsulated in resin or other materials, for protection from chemicals and dirt.

TGA type provided with axial (A) and radial (R) lubrication groves.

TGR type provided with radial (R) lubrication grooves.

Download:

TGU

TGA

Technical Features

Materials

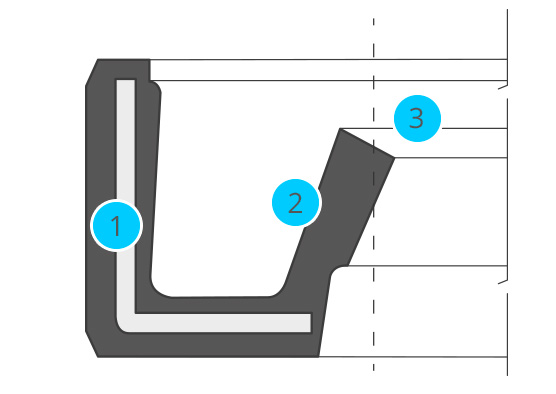

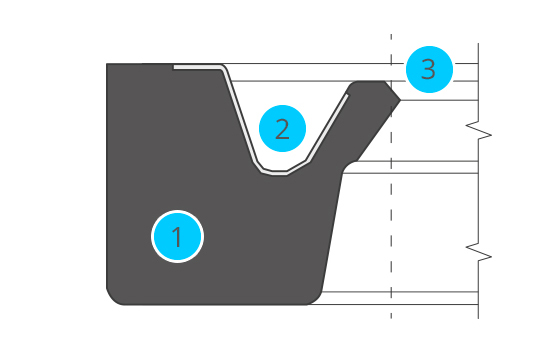

These grease sealing profiles are oil seals with a metal support, but without a garter spring in the sealing lip, and ensure a more delicate contact with the shaft.

This seal is used against grease and dust and is suitable for shafts with low rotating speeds and narrow housing.

For the types GSM and MSM are also available the versions with dust lip: GPSM and MPSM.

Download:

GSM

Technical Features

Materials

Oil seals with external metal casing ground according to FP’s internal specifications and executed in one single piece without welding points.

• The sealing lip is vulcanized directly onto the metal case.

• The type L1 is particularly indicated when there is limited space between the housing and the shaft.

• Also available with an additional dust lip.

Download:

L1

Technical features

Materials

Developed specifically for severe operating conditions with great misalignments and high speeds where rigidity and strength are necessary.

Recovery of misalignment up to 5 mm (radial up to 2,5 mm).

A groove on the external diameter allows the operator to center the oil seal in the housing bore, easing the assembly.

The outer metal case of the oil seal is conceived in one single piece without welding points.

Available on demand with rubber or iron spacers.

The sealing lip is vulcanized onto the metal casing.

Download:

L2M

Technical features

Materials

These shaft oil seals are similar to the L2M® type, and have been developed for small diameter cylinders, starting from 100 mm. For smaller diameters, please contact us to evaluate our production capacity.

Made with a strong external metal casing ground according to FP’s internal specification, onto which is vulcanized the sealing element. Available in various elastomers.

The presence of a forged steel ring bound to the external metal casing, and a finger spring in stainless steel vulcanized with the sealing lip ensure the correct sealing performance, even when shock loads arise.

This oil seal is recommended for applications with grease and low speeds.

An additional dust lip is available upon request.

Download:

L1M

Technical features

Materials

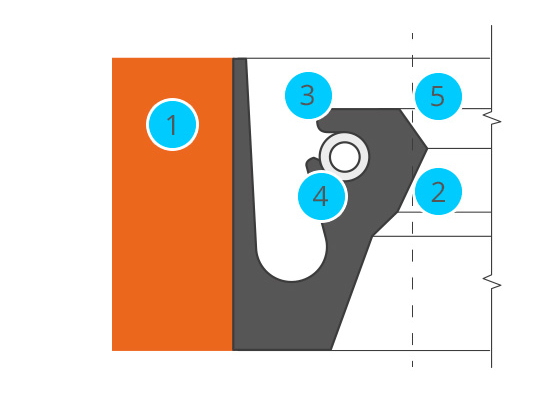

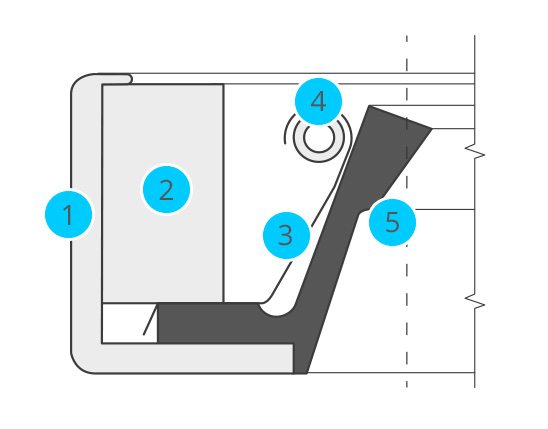

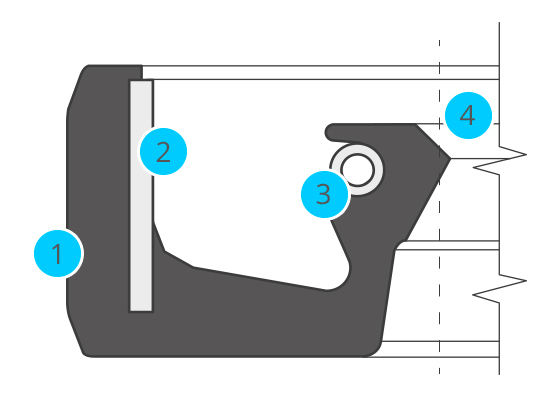

All-rubber oil seal with a vulcanized stainless steel finger spring.

Recommended for difficult assembly conditions and on-site seal replacements which avoid opening the cylinder. It is mostly used in its “split” (open) shape and supplied with the requested length.

In its “endless” (closed) shape, the GM type is suitable as a wiper for hydraulic applications.

Preferably used in applications with grease lubrication and in dusty environments.

The smallest feasible diameter is 100 mm. For smaller sizes contact our offices.

Download:

GM

Technical features

Materials

GM-L2

Technical Features

Materials

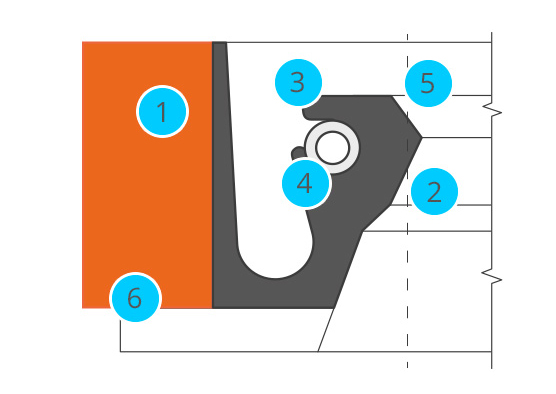

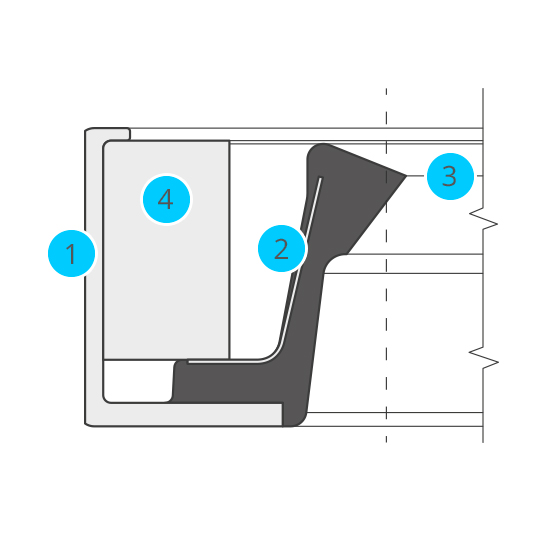

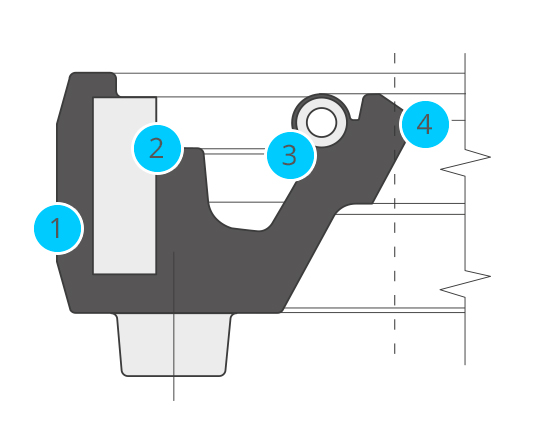

Self-retaining all-rubber oil seal with a vulcanized flexible metal band to be mounted without clamping plate.

Available also in “split” (open) form. Mainly used for maintenance in applications without any pressure. In this case the clamping plate is recommended.

Garter spring available also encapsulated in resin or other materials for protection from chemical aggressions and dirt.

Download:

TGF

Technical features

Materials

Self-retaining oil seal with a rubber covered stiffening metal ring.

Garter spring moulded in the sealing lip.

Available with or w/out built-in spacers for twin mounting systems.

GMA

Technical Features

Materials