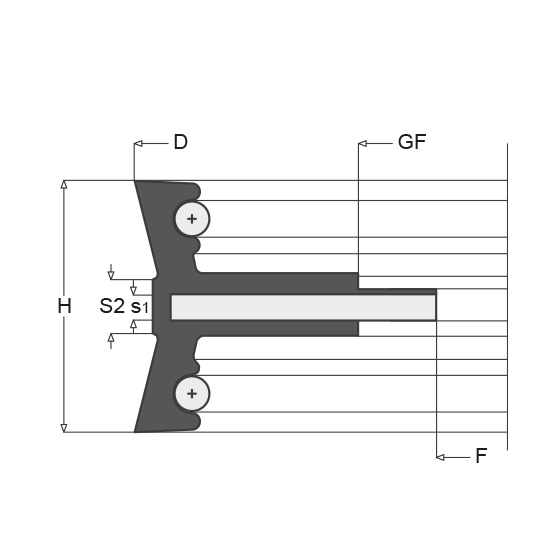

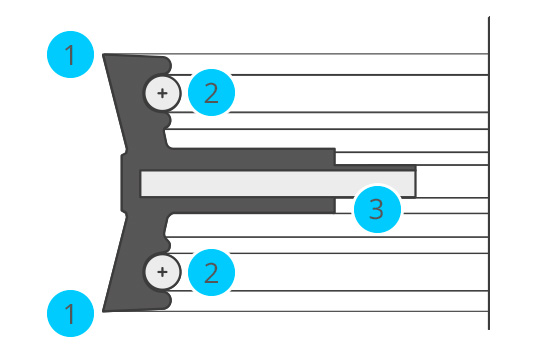

PISTON SEALS (PDE)

The PDE is a symmetric double-acting piston seal for alternative linear movements. Is it designed for oleodynamic applications made in NBR rubber with a hardness of 85 Shore A. It is fitted with expansion garter springs to ensure the correct pressure on the radial contact.

| Applications | Maximum working speed | Operating temp. range | Maximum pressure |

| General industry | up to 0.5 m/s | -30°C / 100°C | 40 BAR (4 MPa) |

Download:

PDE

Technical features

Materials

AISI 302; AISI 304; AISI 316; C72 phosphated

Fe-P11

Constructive directions

CYLINDER DIAMETER

According to tolerance ISO H11

SURFACE ROUGHNESS

Rmax < = 2 μm

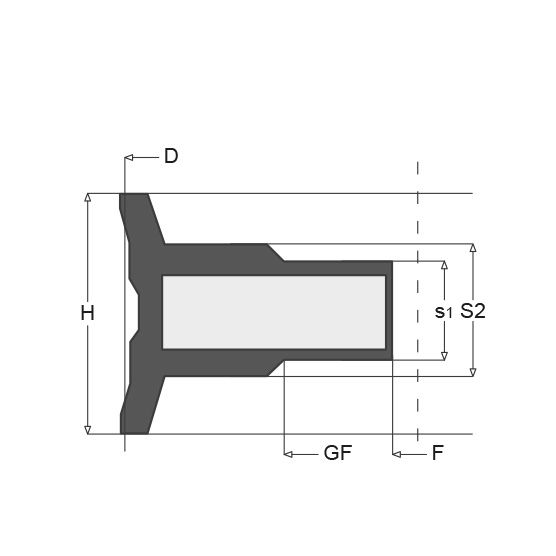

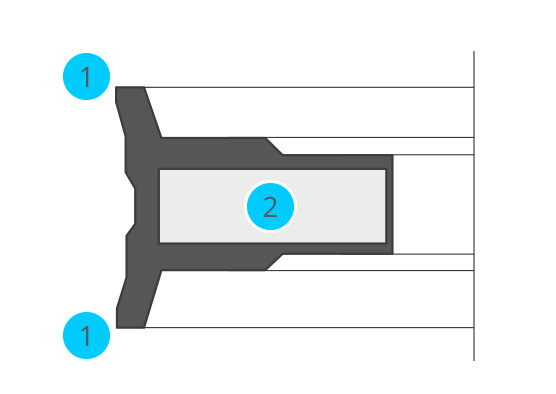

PISTON SEALS (PDEP)

The PDEP is a double-acting piston seal specially designed for pneumatic cylinders. It is made in nitrile rubber (NBR) with a hardness of 70 Shore A with special sealing profiles vulcanized to the central steel plate.

| Applications | Maximum working speed | Operating temp. range | Maximum pressure |

| General industry | up to 0.5 m/s | -30°C / 100°C | 10 BAR (1 MPa) |

Download:

PDEP

Technical features

Materials

Fe-P11

Constructive directions

CYLINDER DIAMETER

According to ISO H11 tolerances

PISTON DIAMETER

According to ISO H10 tolerances

SURFACE ROUGHNESS

Rmax < = 4 μm